Cladco’s cladding options are also moisture resistant, enhancing their longevity and minimising the common upkeep required for different cladding choices. The flammability of cladding materials (aluminium composite panels, insulation, and some other materials corresponding to sarking) is defined primarily based on well-established testing frameworks extensively accepted within the hearth security engineering neighborhood.

The spread of the hearth up the surface wall, if any, was then monitored. The Independent Expert Advisory Panel also suggested the division to establish a research challenge to check and improve the proof out there on the behaviour of a variety of non-ACM supplies utilized in cladding techniques when subjected to fire.

The helium filling gas is also a reasonably good conductor, but solely as long as it remains uncontaminated by fission merchandise. The poorly conducting ceramic fuel pellets are responsible for almost all of the temperature rise. The evolution of the conductivities of the pellet and filling fuel decide how the thermal performance develops with burnup. As the oxide layer grows, the compressive stress at the outer layer of oxide just isn't sustained and consequently the tetragonal part becomes unstable and transforms into the monoclinic part. Such a metamorphosis causes the formation of a fine interconnected porosity in the oxide film which permits the oxidizing water to return in touch with the steel floor.

In other modifications, the sponge zirconium is alloyed with iron or tin to improve oxidation resistance with out affecting the softness that provides immunity from PCI. scale that grows around them throughout in-reactor operation. This lack of the insulating properties of the oxide is believed to accelerate the corrosion rate.

The Building Research Establishment (BRE) has been commissioned to undertake this challenge. This programme is on-going and exams are anticipated to conclude in the summertime.

Zry comes in two varieties, Zry-2 and Zry-four. These two differ by minor modifications in the concentrations of the transition metals (Zry-four has no nickel). PWRs use Zry-four while BWRs employ Zry-2 as cladding and either Zry-2 or Zry-4 for the duct or channel holding the fuel-component bundle. The transition metals iron and chromium appear in the microstructure as precipitates of the intermetallic compounds Zr 2 (Ni,Fe) and Zr(Cr,Fe) 2 . These minor alloying parts improve corrosion resistance to an extent dependent on the dimensions of the precipitates.

With the development of an equilibrium pore and crack construction within the oxide layer, the oxidation fee effectively turns into linear, a characteristic feature of the post-transition oxidation habits. Alloying elements, particularly tin, niobium, and iron, current in the α-strong solution strongly affect both the kinetics and the mechanism of oxide growth in zirconium alloys. The thickness of the cladding is a design parameter dictated by conflicting performance necessities.

laser beam. The alloy was overlaid on the steel as a powder layer 2.5 mm thick.

Due to the collapsible clad design of PHWRs, contact between the pellet and the clad is established proper from the beginning of the lifetime of the gas factor. From subsequent Friday, use of flamable ACM panels such as the Reynobond PE fifty five material that was used on Grenfell Tower will be banned on residential and school buildings above 18 metres excessive. ACM panels were being stripped from 457 high-rise buildings across England, the place they've been found to be in use. But Stephen Hockman QC, counsel for the US industrial firm, said it was “unimaginable to argue that ACM PE was non-compliant†with building laws.

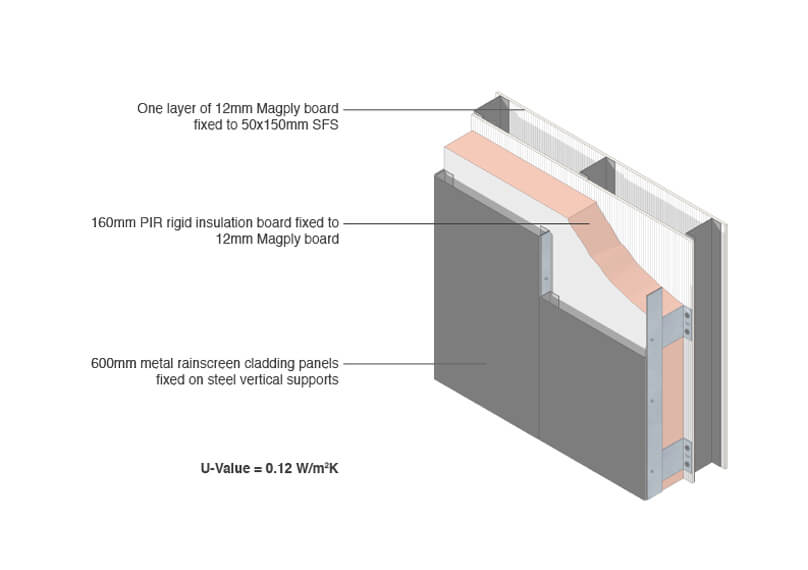

Cladding is an outer layer of either vertical or horizontal materials, used to enhance the looks, thermal insulation and the climate resistance of a building. Our cladding is available in quite a lot of sizes, kinds of timber and floor finishes. Enhance the curb enchantment of your own home with B&Q cladding. All of our timber is responsibly sourced forest friendly timber. Once the pellet/clad gap is closed, any change in pellet dimensions causes stress in the cladding and the synergy between the stress and the corroding medium induces the SCC process.

Cladding (construction)

The prime plate hits the bottom plate with a speed of one hundred–a thousand ms −1 , and pressures are within the vary of 10 to one hundred kbar. Under sure conditions a superheated layer of fabric varieties within the contact space.

The helium filling gasoline can be a reasonably good conductor, however solely so long as it remains uncontaminated by fission products. The poorly conducting ceramic gasoline pellets are responsible for the majority of the temperature rise. The evolution of the conductivities of the pellet and filling fuel decide how the thermal efficiency develops with burnup. As the oxide layer grows, the compressive stress at the outer layer of oxide isn't sustained and consequently the tetragonal phase becomes unstable and transforms into the monoclinic phase. Such a transformation causes the formation of a nice interconnected porosity in the oxide movie which allows the oxidizing water to come in contact with the steel surface.

As a treatment, speedy cooling of the Zry ingot throughout fabrication (known as beta quenching) produces a much finer intermetallic precipitate inhabitants. This distribution of the transition metals maintains the power of the Zry however improves its corrosion resistance, possibly by brief-circuiting charge-transport paths between the size surface and the steel–oxide interface. In order to get rid of waterside corrosion of cladding as a life-limiting process, modified Zircaloys have been developed. Under PWR water conditions, reducing the tin content of Zry to 1% and including a comparable concentration of niobium produces an alloy with a corrosion rate several times lower than that of the standard Zry.

In addition to metallurgical elements, water chemistry has a robust influence on the corrosion process in zirconium alloys. The management of water chemistry as required in several reactor methods include suitable additions of lithium hydroxide, boric acid, hydrogen/deuterium, oxygen, iron, and zinc. In PWRs, boric acid is added to the coolant water for reactivity management. The pH of the coolant is adjusted by addition of lithium hydroxide which renders the coolant barely alkaline, in order to cut back the corrosion rates of structural materials (stainless steels and Inconels) in the primary warmth transport circuit and thereby inhibit deposition of corrosion products on the gasoline cladding. Radiolysis of water produces oxidizing species which boosts oxidation fee of zirconium alloys in the radiation environment .

laser beam. The alloy was overlaid on the metal as a powder layer 2.5 mm thick.

Zry manufacturing methods now provide far better control of gaseous impurities than early fabrication know-how, so the original reason for including tin is moot. Since tin is a substitutional impurity, its perform is to increase the power of Zry over that of pure zirconium.

It comes virtually two years after 72 individuals died within the Grenfell Tower fire. Fire safety specialists warn lots of the 1,seven-hundred buildings recognized as "at risk" in England are prone to fail new exams into cladding and building supplies. , where T is absolutely the temperature and β is the burnup. The constants a and b are fundamental properties of the fabric and could be decided from standard laboratory experiments on contemporary fuel. The thickness of the cladding could range between zero.1 and 30 mm and the detonation velocity is between 1200 and 7000 ms −1 .

The joint is then brought on by a deformation-induced melting bathtub. The melt layer is quite skinny; for instance, when cladding an aluminum alloy it's about 0.5–4μm (Kreye 1985, 1997 ). The dilution of the molten zones ends in airplane or corrugated interfaces.

Zircaloys have anisotropic bodily, mechanical, and chemical properties. Within the oxide layer, the alloying parts influence the atomic transport such that the alloying focus determines the corrosive behavior, with high alloying concentrations (above ∼0.6%) providing protection towards oxide development. Today, Zircaloy-2 and Zircaloy-4 are widely used.

Cladco’s cladding options are additionally moisture resistant, improving their longevity and minimising the regular upkeep required for different cladding options. The flammability of cladding materials (aluminium composite panels, insulation, and another materials similar to sarking) is outlined primarily based on nicely-established testing frameworks broadly accepted in the hearth safety engineering community.

Differential swelling between cladding, wrapper tube, and spacing system (spacer wire or grids) can induce extra stresses and deformations on these components and/or generate coolant move perturbations in the bundle. These phenomena have been studied and have notably proven that wires or grid materials should be chosen and specified to be able to decrease differential swelling. Laser cladding has been utilized to hardening of steam generator turbine blades and reached pilot production standing [four ].

The impact of lack of steel by internal or outer corrosion is less important for thick cladding than for skinny-walled tubing. For the identical exterior loading, the stress produced within the cladding, both exterior from the coolant or inside from fission-product swelling of the fuel, is lowered in proportion to the wall thickness. However, thick cladding is detrimental to neutron financial system, will increase the volume of the reactor core, raises fuel temperature, and costs more than skinny-walled tubing. The compromise between these competing demands has produced wall thicknesses of ∼0.9mm in BWRs and ∼zero.7mm in PWRs. is produced and the risk of a massive secondary hydriding failure is increased.

Moore-Bick has faced widespread calls to conclude in his interim report – expected subsequent spring – that the £10m refurbishment, utilizing highly flamable cladding panels, was in breach of building laws. But he has additionally heard conflicting proof about whether the hearth brigade should have tried to order a full evacuation before the constructing was engulfed in flames trapping and killing households and pals who huddled together in flats. Earlier in Wednesday’s hearing firefighters blamed the Royal Borough of Kensington and Chelsea for failing to make an evacuation plan for Grenfell Tower, regardless of skilled advice taken earlier than the catastrophe and legal obligations making clear it was needed. The efficiency of the uPVC home windows within the fourth ground flat the place the hearth started, the synthetic insulation and other decorative cladding panels across the rest of the building were effectively responsible for spreading the fireplace, he said.

Nuclear Fuels: Behavior at High Burnup

Due to the collapsible clad design of PHWRs, contact between the pellet and the clad is established right from the beginning of the lifetime of the fuel component. From subsequent Friday, use of flamable ACM panels such because the Reynobond PE fifty five materials that was used on Grenfell Tower shall be banned on residential and school buildings above 18 metres high. ACM panels had been being stripped from 457 high-rise buildings throughout England, the place they've been found to be in use. But Stephen Hockman QC, counsel for the US industrial firm, stated it was “unimaginable to argue that ACM PE was non-compliant†with building laws.

The interplay that gas cladding tubes experience as a result of fission merchandise on the internal floor is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are some of the fission merchandise which contribute strongly to the SCC process.

The spread of the hearth up the surface wall, if any, was then monitored. The Independent Expert Advisory Panel also suggested the division to determine a analysis challenge to test and enhance the proof obtainable on the behaviour of a variety of non-ACM materials utilized in cladding systems when subjected to fireside.

Differential swelling between cladding, wrapper tube, and spacing system (spacer wire or grids) can induce further stresses and deformations on these components and/or generate coolant flow perturbations within the bundle. These phenomena have been studied and have notably shown that wires or grid supplies have to be chosen and specified so as to minimize differential swelling. Laser cladding has been applied to hardening of steam generator turbine blades and reached pilot manufacturing standing [4 ].

The fireplace rose 20 storeys in simply 35 minutes to engulf the full height of the tower on 14 June 2017. The inquiry has heard expert proof that the flames unfold via the cladding system and had been fuelled by the extremely combustible panels. Chartered engineer Dr Jonathan Evans was part of the staff testing cladding for the federal government after the Grenfell Tower fire. because of their corrosion resistance to acids and bases and their low neutron-absorption charges.

wedi prefabricated building board Resources elements

The buildup of these can be suppressed by adding hydrogen within the coolant water. Dissolved hydrogen concentration in PWR coolant is maintained at a level of 2.2–4.5 ppm with a view to enhancing recombination with oxygen radicals formed by radiolysis. The PHWR coolant does not contain boric acid and deuterium is added rather than hydrogen. Dissolved oxygen in PHWR coolant is managed between 10–50 ppb and it has been observed that corrosion in both zircaloy-2 and Zr-2.5 Nb strain tubes rises to an exceptionally excessive value at excessive oxygen concentrations.

A suction elimination unit is used to evacuate fastidiously any material waste to be able to avoid bonding flaws because of poor adhesion. Hanover House, a residential tower block in Sheffield, with its cladding partially eliminated after failing fireplace safety tests following the Grenfell Tower hearth. Cladding in building is material utilized over one other to provide a skin or layer and used to offer a level of thermal insulation and weather resistance, and to enhance the appearance of buildings. Between the cladding and the wall there is a cavity where rain can run down. an industrial primer of wooden for facade cladding and prefabricated elements for wood homes.

Most of the steel cladding for the constructing industry is pre-painted in coil previous to the manufacturing of the cladding panels. Metal cladding is used for each safety from environmental components and aesthetics of the constructing. The paint applied by coil coating gives the metal extra sturdiness, corrosion resistance and last appearance. Arconic argued that the tragedy at Grenfell was not the result of its panels, but the combination of supplies used within the 2016 £10m refurbishment, singling out the plastic window frames via which the fire was believed to have first unfold from flat 16 into the cladding system.

Moore-Bick has confronted widespread calls to conclude in his interim report – anticipated next spring – that the £10m refurbishment, using highly flamable cladding panels, was in breach of constructing laws. But he has also heard conflicting evidence about whether or not the fire brigade should have tried to order a full evacuation before the constructing was engulfed in flames trapping and killing households and associates who huddled together in flats. Earlier in Wednesday’s hearing firefighters blamed the Royal Borough of Kensington and Chelsea for failing to make an evacuation plan for Grenfell Tower, regardless of professional advice taken before the catastrophe and authorized obligations making clear it was needed. The efficiency of the uPVC home windows within the fourth floor flat where the hearth began, the synthetic insulation and other decorative cladding panels across the rest of the constructing had been effectively answerable for spreading the hearth, he mentioned.

Zry comes in two varieties, Zry-2 and Zry-four. These two differ by minor changes within the concentrations of the transition metals (Zry-four has no nickel). PWRs use Zry-4 whereas BWRs employ Zry-2 as cladding and both Zry-2 or Zry-four for the duct or channel holding the gasoline-component bundle. The transition metals iron and chromium seem within the microstructure as precipitates of the intermetallic compounds Zr 2 (Ni,Fe) and Zr(Cr,Fe) 2 . These minor alloying elements improve corrosion resistance to an extent dependent on the scale of the precipitates.

Zircaloys have anisotropic physical, mechanical, and chemical properties. Within the oxide layer, the alloying components affect the atomic transport such that the alloying concentration determines the corrosive behavior, with excessive alloying concentrations (above ∼zero.6%) providing safety towards oxide development. Today, Zircaloy-2 and Zircaloy-four are broadly used.

The helium filling gas can also be a reasonably good conductor, however only as long as it stays uncontaminated by fission products. The poorly conducting ceramic fuel pellets are responsible for the majority of the temperature rise. The evolution of the conductivities of the pellet and filling gas determine how the thermal performance develops with burnup. As the oxide layer grows, the compressive stress at the outer layer of oxide is not sustained and consequently the tetragonal part becomes unstable and transforms into the monoclinic phase. Such a metamorphosis causes the formation of a nice interconnected porosity in the oxide film which allows the oxidizing water to come back in touch with the metallic surface.

Phase transformation of Zirconia is, nonetheless, of nice concern. Zircaloys also undergo from dangerous creep rates. In distinction to surface-layer welding, explosive welding causes no change in microstructure, and corrosion resistance of the layers isn't affected (Pocalco 1987 ). ions from the environment to the response entrance at the metallic/oxide boundary.

The interplay that gas cladding tubes experience as a result of fission products on the internal floor is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are some of the fission products which contribute strongly to the SCC course of.

Differential swelling between cladding, wrapper tube, and spacing system (spacer wire or grids) can induce additional stresses and deformations on these elements and/or generate coolant flow perturbations in the bundle. These phenomena have been studied and have notably shown that wires or grid materials should be chosen and specified to be able to decrease differential swelling. Laser cladding has been applied to hardening of steam generator turbine blades and reached pilot manufacturing standing [four ].

The joint is then caused by a deformation-induced melting bath. The melt layer is quite thin; for instance, when cladding an aluminum alloy it's about 0.5–fourμm (Kreye 1985, 1997 ). The dilution of the molten zones ends in plane or corrugated interfaces.

In different modifications, the sponge zirconium is alloyed with iron or tin to enhance oxidation resistance without affecting the softness that provides immunity from PCI. scale that grows around them during in-reactor operation. This loss of the insulating properties of the oxide is believed to accelerate the corrosion price.

Due to the collapsible clad design of PHWRs, contact between the pellet and the clad is established right from the beginning of the life of the gasoline factor. From subsequent Friday, use of combustible ACM panels such as the Reynobond PE 55 materials that was used on Grenfell Tower shall be banned on residential and college buildings above 18 metres high. ACM panels had been being stripped from 457 high-rise buildings across England, where they have been discovered to be in use. But Stephen Hockman QC, counsel for the US industrial firm, mentioned it was “impossible to argue that ACM PE was non-compliant†with constructing rules.